Metal graphite can be divided into copper base metal graphite, aluminum base metal graphite, iron base metal graphite and nickel base metal graphite according to different metal types. Different kinds of metallic graphite have different physical and chemical properties and are suitable for different application fields.

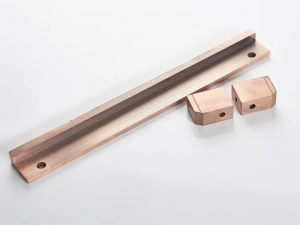

Copper base metal graphite: with high thermal conductivity and high mechanical strength, it is suitable for high-temperature heat exchanger, condenser, heater and other equipment.

Aluminum base metal graphite: with low density, corrosion resistance, high conductivity and other characteristics, it is suitable for aviation, aerospace, automotive and other fields.

Iron base metal graphite: with high strength, high rigidity, high wear resistance and other characteristics, it is suitable for machinery manufacturing, shipbuilding and other fields.

Nickel-based metallic graphite: It has high temperature resistance, corrosion resistance, high strength and other characteristics, and is suitable for aviation, aerospace, nuclear industry and other fields.

The preparation process of metallic graphite mainly includes hot-pressing composite method, arc cladding method and chemical vapor deposition method. Among them, hot-pressing composite method is the most widely used method.

The steps of preparing metallic graphite by hot-pressing composite method are as follows:

1. Make the metal sheet and graphite sheet into the required shape and size.

2. Arrange the metal sheet and graphite sheet in a certain proportion.

3. Put the metal-graphite complex into the hot-pressing equipment for high-temperature and high-pressure hot-pressing.

4. Take out the hot-pressed metal graphite for subsequent processing, such as polishing and cutting.

1. High conductivity: metal graphite has excellent conductivity and can be used to manufacture electrical components such as electrodes, electric heaters, solenoid valves, etc.

2. High thermal conductivity: metal graphite has good thermal conductivity and can be used in high-temperature heat exchangers, condensers, heaters and other equipment.

3. High temperature stability: metal graphite has high oxidation resistance and high temperature resistance, and can work stably under high temperature for a long time.

4. Corrosion resistance: metal graphite has excellent corrosion resistance and can be used to manufacture corrosive media containers in chemical, pharmaceutical and other fields.

5. Low coefficient of thermal expansion: metal graphite has a low coefficient of thermal expansion, which can reduce mechanical deformation and damage caused by temperature changes.

Metallic graphite is widely used in metallurgy, machinery manufacturing, aviation, chemical industry, electronics, medicine, construction and other fields. Specific application areas include:

1. High-temperature devices: such as heat exchanger, heater, vacuum furnace, smelting furnace, etc.

2. Corrosive media containers: such as reactors, tanks, pipelines, etc. in chemical equipment.

3. Aerospace, nuclear industry: such as engine blades, air purifiers, nuclear reactor materials, etc.

4. Electronic and electrical fields: such as conductive plates, insulating materials, semiconductor materials, electrodes, etc.

5. Machinery manufacturing field: such as mechanical seals, cutting tools, bearings, etc.