Copper impregnated graphite is composed of graphite and copper particles. Among them, graphite is a carbonaceous material, which can be divided into natural graphite and artificial graphite. The crystal form of natural graphite is hexagonal sheet, with high crystallinity and high thermal conductivity. It is an excellent thermal conductivity material. The artificial graphite is mainly prepared by high-temperature sintering and other processes, and has the characteristics of good homogeneity and high strength.

Copper particles combine copper and graphite through a specific process to form copper-impregnated graphite. The existence of copper particles can not only enhance the conductivity of graphite, but also improve its strength and hardness, thus enhancing its mechanical properties and wear resistance. In addition, copper particles can effectively reduce the resistivity of graphite and improve its thermal conductivity.

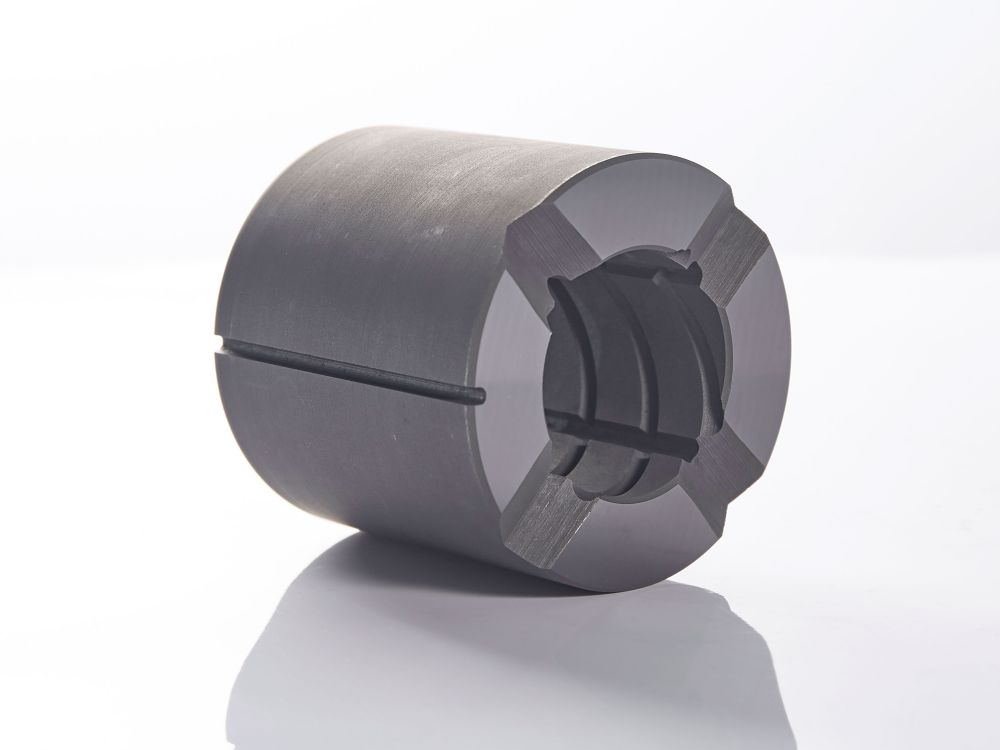

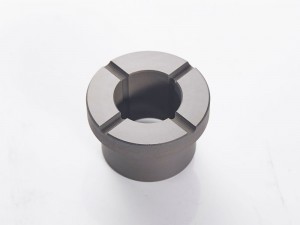

The product forms of copper-impregnated graphite are various, which can be divided into plate, pipe, powder and other forms.

Plate is one of the most common product forms. It is made of graphite and copper powder by high temperature hot pressing process. The thickness is generally between 1mm and 6mm. The length and width can be customized according to actual needs. The surface of the plate is smooth and uniform, and can be machined, processed and punched to meet the needs of different applications.

The pipe is formed by extrusion after mixing graphite and copper particles. Its internal and external surfaces are smooth and uniform. It can be processed with internal holes and external surfaces to manufacture electrodes, capacitors, high-voltage oil-immersed transformers and other devices.

The powder is made of graphite and copper particles through a special grinding process. The particle size of the powder can be adjusted according to the actual needs. It has many contact points and good conductivity. It can be widely used in electronic devices, battery materials and other fields.

The manufacturing process of copper graphite is relatively simple, generally including the following steps:

1. Preparation materials: copper powder and graphite powder shall be mixed in a certain proportion, and a certain amount of lubricant and binder shall be added.

2. Preparation of molding body: press the mixed material into a molding body suitable for processing.

3. Drying and processing: dry the molding, and then process, such as turning, milling, drilling, etc.

4. Sintering: sintering the processed parts to form a solid copper graphite material.

The main characteristics of copper-impregnated graphite are as follows:

(1) Good conductivity: copper impregnated graphite contains a lot of copper particles, which makes its conductivity very excellent.

(2) Good mechanical properties: the presence of copper particles improves the strength and hardness of graphite, making it have good mechanical properties.

(3) Good wear resistance: the presence of copper particles can also improve the wear resistance of graphite.

(4) Good corrosion resistance: graphite itself has good corrosion resistance. With the addition of copper particles, its corrosion resistance is more excellent.

(5) Good thermal conductivity: graphite is an excellent thermal conductivity material. After adding copper particles, its thermal conductivity is even better.

Copper-impregnated graphite has excellent conductivity and mechanical properties, and is widely used in battery materials, thermal management, electronic devices, machinery manufacturing and other fields.

In the field of battery materials, copper-impregnated graphite has been widely used in the preparation of battery electrode plates to improve the performance of batteries due to its excellent conductivity and mechanical properties.

In the field of thermal management, copper-impregnated graphite can be made into heat conducting fins for heat dissipation of various electronic equipment. Because of its excellent thermal conductivity, it can quickly dissipate heat, thus ensuring the long-term stable operation of the equipment.

In the field of electronic devices, copper-impregnated graphite can be used to manufacture capacitors, high-voltage oil-immersed transformers and other devices. Because of its good conductivity, it can effectively transmit electrical signals and energy, so it can meet the needs of various electronic devices.

In the field of machinery manufacturing, copper-impregnated graphite can be made into various shapes of plates, pipes, powders, etc., to meet various needs of machinery manufacturing. At the same time, its wear resistance and corrosion resistance also make it an ideal mechanical manufacturing material.